HEPA filter

The core equipment of the air conditioning purification system, the high-efficiency air conditioning filter is used in the terminal of constant temperature and humidity purification air conditioning, large central air conditioning, and combined air conditioning. The high-efficiency air conditioning filter ensures the air cleanliness of the air outlet.

Applications of HEPA Filters

Indoor Air Purifiers: Many air purifiers use HEPA filters to remove allergens and pollutants from the air, making them ideal for people with allergies or respiratory issues.

HVAC Systems: Some advanced HVAC systems incorporate HEPA filters to improve indoor air quality, especially in hospitals, laboratories, and clean rooms.

Vacuum Cleaners: HEPA filters are commonly found in high-quality vacuum cleaners to prevent fine particles and allergens from being released back into the air during cleaning.

Medical Facilities: HEPA filters are crucial in healthcare settings to help control airborne contaminants and maintain sterile environments.

Quick Links

CleanRoom Equipments Manufacturer

Deiiang stands for "Cleanroom Manufacturer", which is our core business tenet, and it enables us to push boundaries and expand from China to Southeast Asia, North America and Europe as a professional supplier of controlled environment solutions to meet the needs of the global market. Deiiang will provide users with the best solutions by understanding their process requirements.

- Video

- Workshop

- Data sheet

- Material certificate

HEPA filter without partition

With its excellent design and performance, the compartmentless filter has become an indispensable part of modern air purification systems.

DOP Integrated Filter

In modern cleanroom technology, DOP integrated high-efficiency filters have become important equipment for various high-cleanliness environments due to their excellent performance and convenient use.

Knife rack type non-partition HEPA filter

With its excellent filtration performance and advanced design, knife-rack, compartmentless HEPA filters have become a key device for air pollution control in a number of industries.

Tank type HEPA filter without partition

With its high efficiency filtration performance, high quality materials and unique design, the liquid tank type high efficiency filter without partition is widely used in clean rooms and environments with very high requirements for air quality.

ULPA Filter without Compartment

In today's world of air quality control and purification, the choice of filtration technology is critical, and ULPA-rated Ultra Low Penetration Air Filters and HEPA-rated High Efficiency Particulate Air Filters (HEPA) are two of the most widely used filter types.

High Temperature Separated HEPA Filter

With the acceleration of industrialization, especially in the fields of painting, baking and sterilizing under high temperature environment, the requirements for air quality are getting higher and higher.

Products Video

Related Products

Help to Find Your Cleanroom Related Products

FAQ

Can a HEPA filter be washed?

HEPA filters should not be washed. Here’s an analysis of why washing HEPA filters is not recommended:

Structural Integrity

Deformation: Washing can cause the filter to lose its shape, leading to gaps where unfiltered air can bypass the filter.

Effectiveness

Washing may not remove all trapped particles, and the remaining debris can obstruct airflow and reduce filtration efficiency.

Drying Issues

Moisture Retention: After washing, HEPA filters can retain moisture, which can lead to mold and bacteria growth within the filter.

Manufacturer Guidelines

Instructions: Most manufacturers explicitly state that HEPA filters should not be washed.

What do HEPA filters not remove?

HEPA filters are highly effective at capturing a wide range of airborne particles, but there are certain types of contaminants that they do not effectively remove. Here are some key categories of particles and substances that HEPA filters cannot eliminate:

1. Gases and Vapors

Volatile Organic Compounds (VOCs): These include a variety of chemicals found in paints, cleaners, and other household products.

2. Smoke

Fine Smoke Particles: While HEPA filters can capture larger particulate matter from smoke, they may not be as effective against very fine particles present in smoke, especially from sources like wildfires or tobacco.

3. Bacteria and Viruses

While HEPA filters can trap a significant percentage of bacteria and viruses due to their small size (typically 0.3 microns and larger), they do not eliminate them entirely.

4. Large Particles

Dust and Pollen: HEPA filters are designed to capture particles as small as 0.3 microns, so larger particles like dust and pollen can also be filtered out.

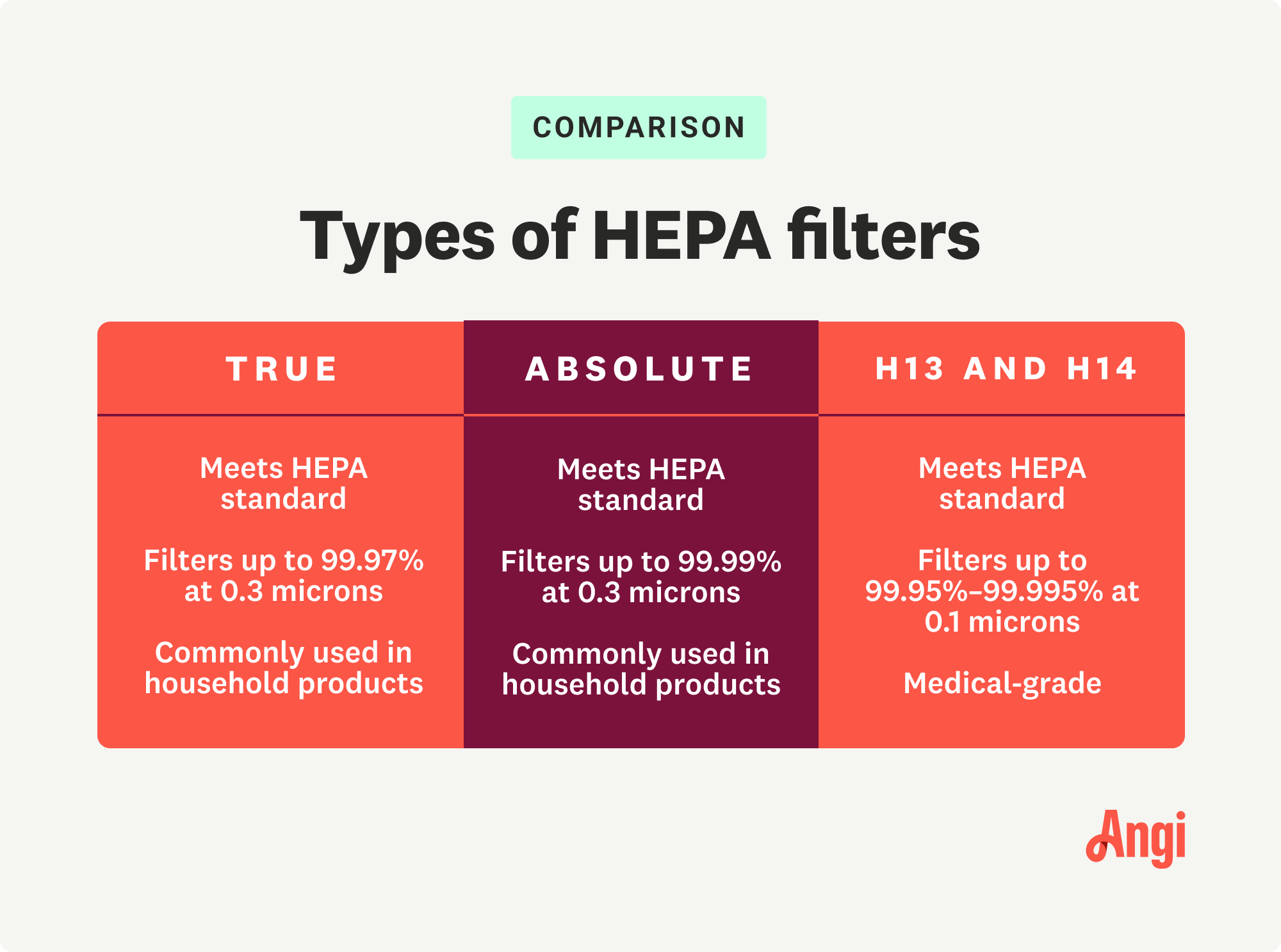

How are HEPA filters classified?

1. Classification Standards

HEPA filters are often classified according to standards set by various organizations. The most recognized standards include:

H10 to H12: These filters have efficiencies ranging from 85% to 99.5% for particles of 0.1 to 0.3 microns.

H13 and H14: These are higher-efficiency filters, capturing 99.95% and 99.995%, respectively, of particles down to 0.1 microns.

2. Efficiency Classes

HEPA: Standard HEPA filters that meet the DOE requirement (99.97% at 0.3 microns).

ULPA (Ultra Low Penetration Air): Filters that capture 99.999% of particles down to 0.12 microns.

What is HEPA H13 classification?

1. HEPA H13 filters remove 99.95% of particles ≥0.3 microns.

2. It is widely used in cleanrooms, hospitals, and laboratories to maintain air quality.

Relevant Standards List:

ISO 14644-1 (Cleanroom standards)

EN 1822 (HEPA filter classification)

ASHRAE 52.2 (Air filter performance standards)

What is HEPA filter grade?

HEPA filters are categorized by their efficiency in removing airborne particles. Higher grades have better filtration efficiency.

H13 removes 99.95% of particles.

H14 removes 99.995% of particles.

Grades determine suitability for specific clean environments.

Certified according to international standards.

Efficient at capturing bacteria and viruses.

Used in critical industries like healthcare and electronics.

The grade of a HEPA filter determines its application and performance in various clean environments.

How many types of HEPA filters are there?

1. H10–H12: Medium efficiency filters.

2. H13–H14: High-efficiency filters for critical environments.

3. U15–U17: Ultra-high efficiency filters.

4. Classified by EN 1822 standards.

Different types cater to varying levels of air purity requirements, from residential to industrial and cleanroom applications.

What are HEPA filters used for?

1. HEPA filters ensure ultra-clean air in critical settings such as hospitals, laboratories, and cleanrooms.

2. They are also used in residential, commercial, and industrial settings to improve indoor air quality.

How much does a HEPA filter cost?

The cost depends on size, grade, and application, ranging from affordable to premium options.

Entry-level filters cost ~$100–$500.

High-grade cleanroom filters can exceed $1,000.

Maintenance costs can add to the overall expense.

How much does it cost to install a HEPA filter?

1. Typical installation ranges from $200–$500.

2. Complex systems or custom setups may cost more, depending on the requirements.

Relevant Standards List:

ISO 14644-2 (Cleanroom maintenance)

EN 779 (General air filtration classification)

Why is HEPA so expensive?

HEPA filters are expensive due to their precision, durability, and superior performance.

1. Advanced manufacturing processes.

2. High-cost materials.

3. Rigorous testing and certification.

4. Long-term durability.

5. High filtration efficiency.

6. Specialized applications.

Though costly, HEPA filters are indispensable in environments requiring strict air quality standards.

Are HEPA filters worth the cost?

1. Yes, for critical environments like cleanrooms.

2. Improves health and safety by removing contaminants.

3. Ensures compliance with cleanroom regulations.

4. Long-term reliability offsets initial expense.

The investment in HEPA filters is justified by their efficiency and reliability in maintaining clean environments.

What class is a HEPA filter?

1. H13 is classified as high-efficiency.

2. H14 is ultra-high efficiency.

3. Classes vary based on specific use cases.

4. Certified under EN 1822.

HEPA classes ensure tailored solutions for diverse air quality needs.

What is the difference between H13 and H14 HEPA filter?

1. H14 has a higher filtration efficiency (99.995%) than H13 (99.95%), capturing finer particles.

2. H14 is suited for stricter environments like pharmaceutical manufacturing, while H13 is ideal for general cleanrooms.

MENU

MENU +86 18186671616

+86 18186671616 Pengwu1616@Gmail.com

Pengwu1616@Gmail.com