MENU

MENUX

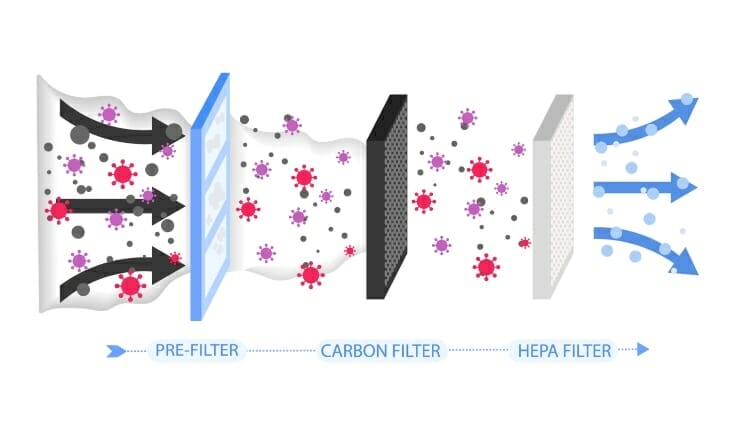

An HVAC air filter is a crucial component in heating, ventilation, and air conditioning (HVAC) systems. It is designed to trap dust, dirt, allergens, and other particles from the air as it circulates through the system, improving indoor air quality and ensuring that the HVAC system operates efficiently.

Fiberglass Filters

Pleated Filters

High-Efficiency Particulate Air (HEPA) Filters

Electrostatic Filters

Activated Carbon Filters

Media Filters

Carbon & HEPA Hybrid Filters

Bag Filters

Min. Order:1 unit

Catalog:HEPA filter without partition

Min. Order:

Catalog:HEPA filter without partition

Min. Order:

Catalog:HEPA filter without partition

Min. Order:

Catalog:HEPA filter without partition

Min. Order:

Catalog:HEPA filter without partition

Min. Order:

Catalog:HEPA filter without partition

Min. Order:

Catalog:HEPA filter without partition

Min. Order:

Catalog:HEPA filter without partition

Min. Order:

Catalog:HEPA filter without partition

Min. Order:1 unit

Catalog:Medium Efficiency Glass Fiber Bag Filter

Min. Order:1 unit

Catalog:Medium Efficiency Glass Fiber Bag Filter

Min. Order:1 unit

Catalog:Medium Efficiency Glass Fiber Bag Filter

Min. Order:1 unit

Catalog:Medium Efficiency Glass Fiber Bag Filter

Min. Order:1 Set

Catalog:Medium Efficiency Glass Fiber Bag Filter

Min. Order:1 unit

Catalog:Medium Efficiency Glass Fiber Bag Filter

Min. Order:1 unit

Catalog:Medium Efficiency Glass Fiber Bag Filter

Min. Order:1 unit

Catalog:Medium Efficiency Glass Fiber Bag Filter

Min. Order:1 unit

Catalog:Medium Efficiency Glass Fiber Bag Filter

Min. Order:1 unit

Catalog:Medium Efficiency Glass Fiber Bag Filter

Min. Order:1 unit

Catalog:Medium Efficiency Glass Fiber Bag Filter

Min. Order:1 unit

Catalog:Medium Efficiency Glass Fiber Bag Filter

Min. Order:1 unit

Catalog:Chemical fiber bag type medium effect filter

Min. Order:1 unit

Catalog:Chemical fiber bag type medium effect filter

Min. Order:1 unit

Catalog:Chemical fiber bag type medium effect filter

Modular CleanRoom

US$9000-10000 USD/Unit

Min. Order:1 unit

Air Shower

US$1000.00-5000.00 USD/Unit

Min. Order:1 unit

Downflow Booth

US$3000-6000 USD/Unit

Min. Order:1 unit

Clean bench

US$600-2000 USD/Unit

Min. Order:1 unit

Air Filter

US$3-50 USD/Unit

Min. Order:1 unit

Cleanroom Wall Panels

US$10-20 USD/sq.

Min. Order:100 square

Deiiang is a trusted manufacturer of high-efficiency air filters, including HEPA, ULPA, and industrial-grade solutions, serving sectors like healthcare, electronics, and cleanroom facilities. With ISO 9001 certification and adherence to EN 1822 and ASHRAE standards, we ensure unmatched air purity, durability, and energy efficiency. Our commitment to innovation and rigorous quality control positions us as a go-to partner for businesses prioritizing clean air and operational reliability.

At Deiiang, we combine cutting-edge technology with sustainable practices to produce air filters that exceed industry expectations. Our product portfolio includes:

Customizable Designs: Filters engineered for specific airflow, particle retention, and environmental needs.

Certified Performance: Compliance with EN 1822, IEST, and ASHRAE standards for consistent reliability.

End-to-End Support: From prototype development to after-sales service, we ensure seamless integration and long-term performance.

HEPA filters are not washable. HEPA filters are made of delicate materials and are designed for single use, not suitable for washing. Cleaning may damage the filter material, resulting in reduced filtration efficiency.

Replace the filter. In order to maintain efficient filtration performance, HEPA filters should be replaced regularly. It is generally recommended to replace them every 6 to 12 months, depending on the usage environment.

Gases and Vapors: HEPA filters do not remove gases, fumes, or vapors like volatile organic compounds (VOCs) or odors, as they only filter out solid particles.

Very Small Particles: While HEPA filters capture 99.97% of particles down to 0.3 microns, they may be less effective at trapping particles smaller than this, such as some nanoparticles.

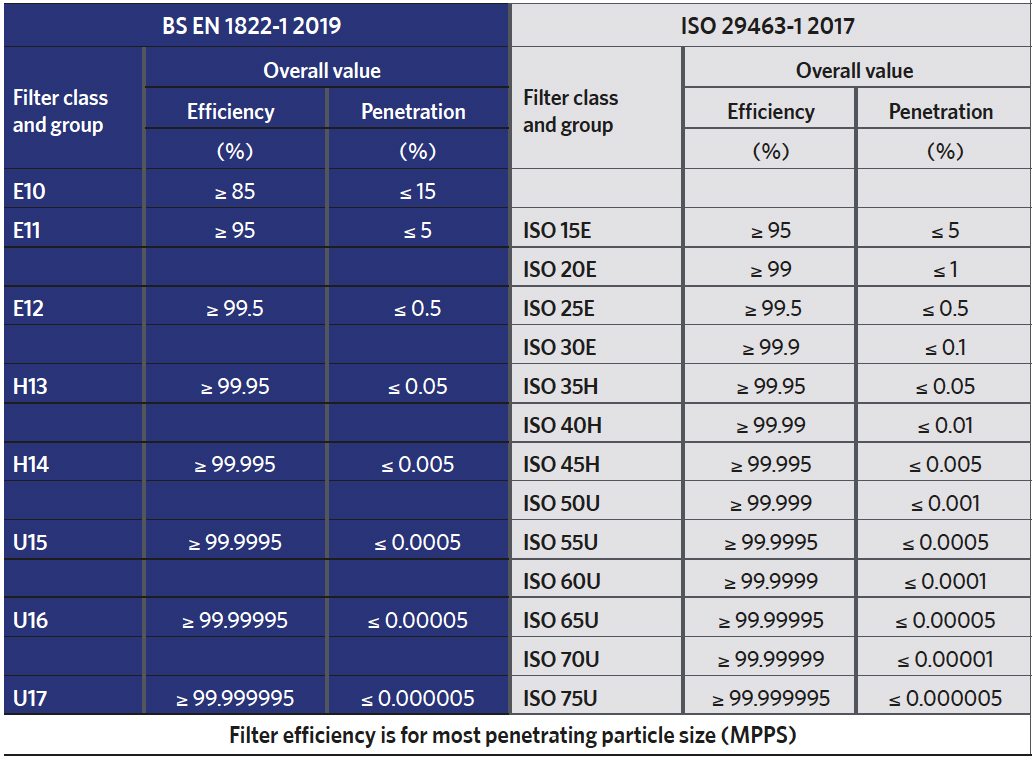

HEPA filters are classified by their filtration efficiency. The standard HEPA filter captures at least 99.97% of particles ≥0.3 microns in size. Higher grades, like ULPA filters, can capture even finer particles.

Different regions have specific standards for HEPA classification. For example, in the U.S., HEPA filters are defined by IEST-RP-CC001.3 standard, while Europe follows the EN 1722 standard, categorizing filters from H13 to H14.

HEPA filters are also classified based on their use, such as industrial, medical, and residential filters. Different applications require different grades of filtration, depending on the required air purity.

HEPA H13 Classification: HEPA H13 filters are classified as high-efficiency filters that capture 99.95% of particles as small as 0.3 microns. They are commonly used in cleanrooms, hospitals, and other environments where high air quality is essential.

Application and Standards: In the EN 1722 standard, H13 filters are one of the highest grades, offering excellent particle removal efficiency, making them suitable for critical applications in medical, pharmaceutical, and industrial settings.

The grade of a HEPA filter refers to its filtration efficiency at trapping particles of a specific size. For example, a standard HEPA filter captures at least 99.97% of particles that are 0.3 microns in diameter.

HEPA filters are classified into various grades, such as H13 and H14 under the EN 1722 standard, based on their particle capture efficiency. Higher grades, like ULPA, can trap smaller particles with even greater efficiency.

Different HEPA grades are used in varying environments, with H13 and H14 filters typically found in cleanrooms, laboratories, and medical facilities, where high air quality is crucial for safety and contamination control.

H10: A basic level HEPA filter, providing lower filtration efficiency.

H11: A standard filter with medium filtration efficiency for less sensitive environments.

H12: Offers high filtration efficiency, often used in commercial applications.

H13: Offers a very high level of particle filtration, often used in medical and pharmaceutical environments.

H14: Provides the highest filtration efficiency, used in critical cleanrooms and laboratories.

HEPA filters are available in various types, classified based on efficiency, application, and filtration methods.

HEPA filters are primarily used in air purifiers to clean indoor air by trapping dust, pollen, mold spores, pet dander, and other airborne particles. They are common in homes, offices, and healthcare settings to improve air quality.

HEPA filters are used in cleanrooms, hospitals, and laboratories to prevent contamination in environments requiring strict air purity, such as pharmaceutical manufacturing, surgery rooms, and electronics production.

Standard HEPA Filters: The cost of a typical HEPA filter for home air purifiers or HVAC systems ranges from $20 to $150, depending on the brand, size, and application.

Industrial and Specialized Filters: For industrial or medical applications, HEPA filters can cost significantly more, with prices ranging from $500 to $5,000 or more, depending on the specifications and efficiency required for the environment.

HEPA filters are made from advanced materials that require precise manufacturing processes to ensure high filtration efficiency (99.97% for particles ≥0.3 microns), contributing to their higher cost.

HEPA filters are often used in critical environments, such as cleanrooms and medical facilities, where air quality is vital. Their ability to meet stringent standards for particle removal and durability increases both their price and demand.

The main difference between H13 and H14 HEPA filters lies in their filtration efficiency:

H13 HEPA Filter: Captures at least 99.95% of particles ≥0.3 microns in size.

H14 HEPA Filter: Captures at least 99.995% of particles ≥0.3 microns, offering slightly higher efficiency than H13.